After an intense hour-long session with a trained watchmaker, here’s how I put together Jaeger-LeCoultre’s Caliber 770 — an exercise in patience, persistence and perfection

Dexterity, focus, precision and a strong eyesight to work with extremely small components are some of the essentials for any watchmaker. I believed I ticked all the boxes until I attended my first-ever watchmaking class.

Earlier this year, Jaeger-LeCoultre had invited us to the “Reverso Stories” exhibition at its flagship boutique in Hong Kong. It was a rare opportunity to experience the brand’s heritage up, close and personal – not only did I see some of the original Reversos from the 1930s but also tried my hand at perlage – a decorative technique used to adorn the bridges and plates on a watch movement with overlapping circular patterns made with the help of a rotating peg. I’ve been writing about watches for nearly six months now and this experience really piqued my interest in watchmaking. So when I was offered a special class with Jason Hung, Jaeger-LeCoultre resident watchmaker in Hong Kong, I was thrilled to bits!

Right from the tools to the techniques – Jason introduced me to the basics of watchmaking in an hour-long session, which (mildly put) was quite intense. Now, I totally understand why these ateliers are located in serene and picturesque places like Switzerland and how these watchmakers need to be in a zen zone all the time.

The Tools

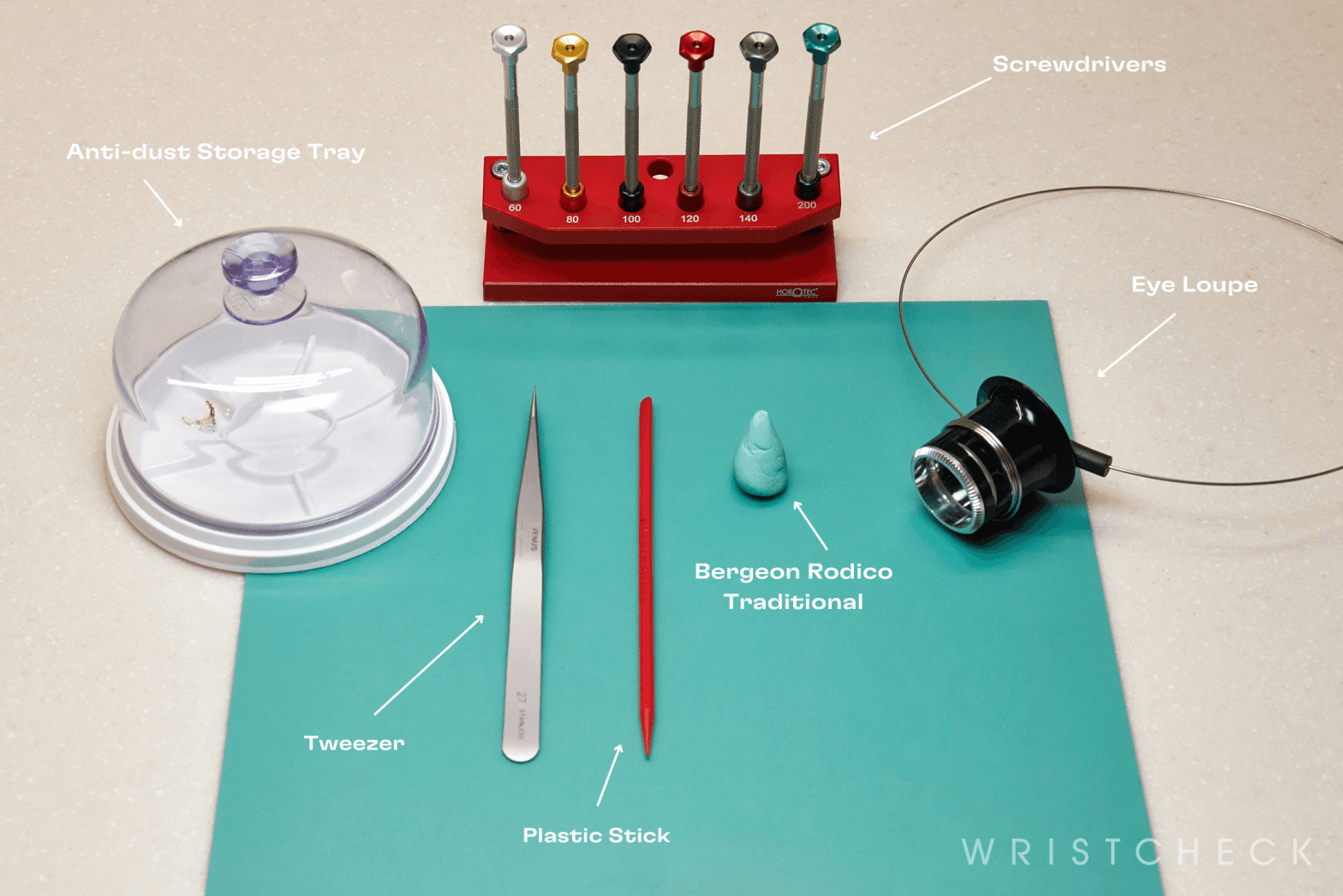

First things first, Jason introduced me to some of the tools used in watchmaking. He explained that though some of the tools may appear to be redundant at first, there is a reason why they are essential to the whole process.

We start with the much-needed anti-dust storage tray that keeps everything in place, after each step of unscrewing and storing the components. One of the most commonly used tools are screwdrivers in sizes 120 and 140. Now to use the screwdrivers, there was a special technique and finger placement: index finger on top, thumb, and middle fingers to screw, or unscrew. This method really helps because it divides the amount of pressure put on the screw-head and gives you a precise grip.

Next up, tweezers. They're intended to be extremely handy when managing small screws and moving them to and from the tray. Another item I majorly underestimated was this plastic stick used for precise placements of delicate and fragile parts. The magnifier or eye loupe comes in handy when you are working with components barely visible to the naked eye. Finally, Bergeon Rodico Traditional is a versatile tool, somewhat similar to blu-tack in appearance and texture, but it's less adhesive and sticky. This is really useful if you need to move screws or jewels, or if you want to avoid fingerprints and dust when cleaning a piece.

The Movement

Placed right in the center of a brightly lit desk was the Caliber 770 – my playing field for the day. Featuring a date function, as well as true seconds, this movement debuted in Jaeger-LeCoultre’s Geophysic model (now discontinued) in 2015. One of the highlights of this movement was the Gyrolab balance – made in-house at the brand’s manufacture and it was this particular component that really pushed my abilities to be a watchmaker for the day.

Disassembly

To be honest, the first five minutes can be a bit mind-boggling if you are not familiar with the names of different components. I started to unscrew the bridges, which revealed the gear train: barrel, center wheel, third wheel, fourth wheel, escape wheel and balance wheel.

Watchmaking engages all your senses to full capacity, not just your eyes but ears too. I was asked to pay attention to the intricacies of sound while screwing or unscrewing the components. If you hear a click during unscrewing, it means the screw is ready to be removed. I discovered that in case of super tiny screws, this sound indication comes really handy.

Another important tip, don’t be in a rush. “Be slow, be patient and move lightly”, Jason kept reminding me these three things throughout the session. One also needs to be mindful and focused because any sort of extra pressure can damage the screw head or, in some cases, the movement itself.

I managed to disassemble the movement in around 20–25 minutes. While minor mistakes were made all along–picking up a screw with my finger instead of a tweezer or placing a screw outside the tray and momentarily losing it – I quite enjoyed the first part of the task.

Before heading onto the next step, we took a little break to inspect the components more closely under a microscope. It was quite amusing! The last time I used a microscope was to examine the peel of an onion during my science class in 2010.

Assembly

Time for assembly. To be frank, I was already a little disoriented. It was like gazing at jigsaw pieces waiting to be put together. I started off with the escape wheel, balance wheel, fourth wheel, third wheel, center wheel, and barrel. The jewels made things a little easier as I knew just where to place the wheels. Fun fact: traditionally, these watchmaking jewels were made with actual rubies and their primary purpose was to act as a bearing for the caliber's small components. Nowadays most timepieces utilize synthetic rubies.

The most difficult steps in this stage involved the setting of the palette fork and balance wheel. It was difficult for two reasons: the palette fork is extremely small, and the balance wheel – incredibly fragile, it is thinner than human hair. Given that it was my first attempt and the first time I had ever seen the inside of a caliber, I nailed it on the first try. Call it beginner's luck or whatever, but I was thrilled with how I fared.

Following the positioning of the wheels after the escape wheel, it was necessary to use the plastic stick to gently spin it to test if the wheels rotated. First, I used the loupe to ensure that each wheel's teeth were perfectly aligned with the other. Then, I rotated the barrel, which gives energy to the entire movement, to see if all of the wheels were turning. This step is absolutely crucial, according to Jason, because if you screw up and fail to check at every stage, you'll have to unscrew everything just to correct that one component. The moment of true delight–seeing the entire movement come to life after placing the balance wheel, also known as the heart of a watch! It was the most gratifying and rewarding part of the entire process. Phew.

Even though I’ve only spent around an hour as an amateur watchmaker, I now genuinely understand why watches are such priced luxuries. Making or restoring a watch takes great patience, lots of attention and sometimes months or even years to complete a project. My eyes felt really strained and I had to look at something other than the caliber every 10 minutes to get my focus back.

The Most Important Lessons

Learning the fundamentals of watchmaking was an insightful and fascinating experience, and I'm seriously considering enrolling in a more in-depth course. To top it off, I also received Jaeger-LeCoultre's certification towards the end of the class. What’s a lesson without an evaluation from the instructor? "You seem to be in a hurry," said Jason, who graduated from Richemont Watchmaking School and has worked with Cartier previously. “You have an excellent eye and a steady hand, but you must be more patient. You installed the balance wheel hairspring in a single shot. Overall, I give your effort an 8 out of 10,” he said. I couldn’t be happier. "3 P's of watchmaking," as my colleague, Neha, mentioned, "patience, persistence, and perfection." That’s what it takes.

Editor’s Note: *The Jaeger-LeCoultre watchmaking class is only available to selected clients.